Hauv metallurgy, ob qho tib si overheating thiab overburning yog cov ntsiab lus hais txog kev kho cua sov ntawm cov hlau, tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem xws li forging, casting, thiab kev kho cua sov. Txawm hais tias lawv feem ntau tsis meej pem, cov xwm txheej no hais txog ntau theem ntawm kev puas tsuaj thaum tshav kub kub thiab muaj kev cuam tshuam rau cov hlau. Kab lus no muab cov ntsiab lus ntawm overheating thiab overburning, ua raws li kev tshawb fawb ntawm lawv qhov sib txawv tseem ceeb.

Overheating:Overheating yog hais txog ib qho xwm txheej uas cov hlau tau rhuab tshaj qhov ntsuas kub uas tau pom zoo, ua rau cov pob zeb ntxhib. Hauv cov pa roj carbon steel (ob leeg hypoeutectoid thiab hypereutectoid), overheating feem ntau yog tshwm sim los ntawm kev tsim cov qauv Widmanstätten. Rau cov cuab yeej steel thiab high-alloy steels, overheating manifests raws li lub angular duab ntawm thawj carbides. Hauv qee cov hlau alloy, overheating kuj tuaj yeem ua rau nag lossis daus ntawm cov khoom raws li cov ciam teb. Ib qho ntawm cov kev txhawj xeeb tseem ceeb nrog overheating yog qhov ua rau cov nplej ntxhib tuaj yeem cuam tshuam cov khoom siv hluav taws xob ntawm cov hlau, ua rau nws tsis tshua muaj ductile thiab nkig. Txawm li cas los xij, feem ntau, qhov kev puas tsuaj los ntawm overheating tuaj yeem txo qis lossis txawm rov qab los nrog kev kho cua sov kom zoo.

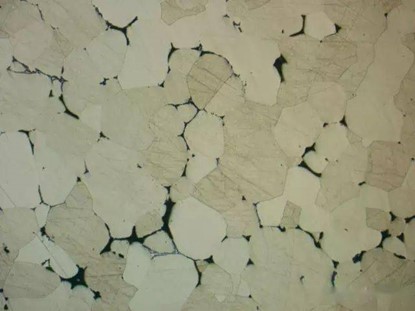

Overburning:Overburning yog ib qho mob hnyav dua piv rau overheating. Nws tshwm sim thaum cov hlau raug kub dhau ntawm nws qhov melting point, ua rau cov khoom deteriorate dua li kho. Hauv cov hlau hnyav heev, cov kab nrib pleb tuaj yeem tsim nrog kev ntxhov siab tsawg thaum lub sij hawm deformation. Piv txwv li, thaum cov hlau kub hnyiab raug ntaus thaum muaj kev ntxhov siab, nws tawg yooj yim, thiab thaum lub sij hawm elongation, cov kab nrib pleb tuaj yeem tshwm. Cov chaw overburned yog qhov txawv los ntawm cov nplej ntxhib heev, thiab cov pob txha tawg feem ntau pom cov xim grey-xiav. Nyob rau hauv aluminium alloys, overburning ua rau saum npoo rau darken, feem ntau tsim ib tug dub los yog tsaus grey xim nrog ib tug blistered, pockmarked tsos. High magnification qhia tau hais tias overburning feem ntau yog txuam nrog oxidation thiab melting raws lis ciam teb. Nyob rau hauv cov xwm txheej hnyav, liquation tuaj yeem tshwm sim ntawm thaj tsam ntawm cov qoob loo, ua rau cov khoom ua kom puas irreversibly.

Qhov txawv tseem ceeb:Thawj qhov sib txawv ntawm overheating thiab overburning yog nyob rau hauv qhov hnyav thiab mus tas li ntawm kev puas tsuaj. Overheating ua rau cov nplej coarsening, tab sis cov hlau feem ntau tuaj yeem rov qab los rau nws qhov qub qub los ntawm txoj kev kho cua sov kom zoo. Kev puas tsuaj feem ntau txwv rau kev hloov pauv hauv microstructure thiab tsis ua rau muaj kev puas tsuaj sai sai tshwj tsis yog tias cov khoom raug cuam tshuam rau kev ntxhov siab heev.

Ntawm qhov tod tes, overburning sawv cev rau ib qho teeb meem tseem ceeb dua qhov uas cov khoom raug puas irreversible. Lub melting los yog oxidation ntawm grain ciam teb txhais tau hais tias cov hlau nyob rau hauv cov qauv yog compromised tshaj kho. Overburning ua rau brittleness thiab cracking, thiab tsis muaj ib tug npaum li cas ntawm kev kho cua sov tom qab yuav rov qab tau cov khoom ntawm mechanical zog.

Hauv cov ntsiab lus, overheating thiab overburning yog ob qho tib si cuam tshuam rau cov cua kub ntau dhau, tab sis lawv txawv ntawm lawv qhov cuam tshuam rau cov hlau. Overheating feem ntau yuav thim rov qab, thaum overburning ua rau irreversible kev puas tsuaj, uas ua rau ib tug tseem ceeb poob ntawm cov khoom ncaj ncees. Kev nkag siab txog qhov sib txawv no yog qhov tseem ceeb rau kev ua kom muaj kev tswj xyuas qhov kub thiab txias kom zoo thaum lub sij hawm metallurgical txheej txheem, tiv thaiv cov khoom tsis ua hauj lwm thiab ua kom lub neej ntev ntawm cov khoom hlau.

Post lub sij hawm: Oct-08-2024