Cov ntsiab lus carbon hauv cov hlau yog ib qho tseem ceeb tshaj plaws uas cuam tshuam rau weldability ntawm forging cov ntaub ntawv. Hlau, sib xyaw ua ke ntawm hlau thiab carbon, tuaj yeem muaj cov ntsiab lus sib txawv ntawm cov pa roj carbon monoxide, uas cuam tshuam ncaj qha rau nws cov khoom siv kho tshuab, suav nrog lub zog, hardness, thiab ductility. Rau welded forgings, kev nkag siab txog kev sib raug zoo ntawm cov ntsiab lus carbon thiab vuam kev ua tau zoo yog qhov tseem ceeb los xyuas kom meej qhov kev ncaj ncees thiab zoo ntawm cov pob qij txha welded.

Tsawg-carbon steels, feem ntau muaj tsawg dua 0.30% carbon, yog cov khoom siv weldable tshaj plaws. Cov hlau no muaj qhov zoo ductility thiab malleability, ua rau lawv zoo tagnrho rau ntau yam kev siv vuam. Cov ntsiab lus qis dua yuav txo qhov kev pheej hmoo ntawm kev tawg hauv thaj chaw kub ntxhov (HAZ) thaum thiab tom qab vuam. Qhov no yog vim cov pa roj carbon tsawg ua rau qis hardenability, txhais tau hais tias cov khoom siv tsis tshua muaj peev xwm tsim cov microstructures xws li martensite, uas tuaj yeem muaj teeb meem hauv thaj chaw welded. Yog li, forgings nrog cov ntsiab lus carbon tsawg yuav muaj teeb meem tsawg dua rau kev tawg lossis tawg thaum lub sijhawm vuam txheej txheem.

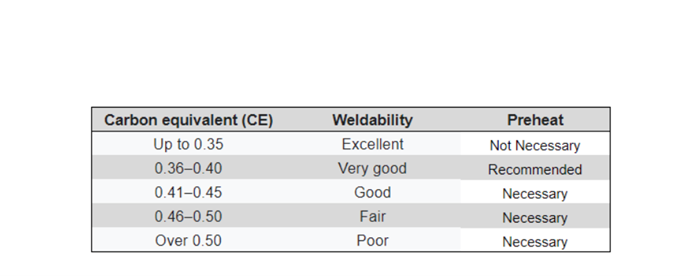

Nyob rau hauv sib piv, raws li cov ntsiab lus carbon nce, lub weldability ntawm steel diminishes. Medium-carbon steels, nrog cov ntsiab lus ntawm cov pa roj carbon monoxide ntawm 0.30% thiab 0.60%, muab lub zog thiab hardness ntau dua piv rau cov hlau tsis muaj roj carbon tsawg tab sis tuaj nrog kev pheej hmoo ntxiv thaum vuam. Cov ntsiab lus carbon ntau dua ua rau muaj zog dua, uas ua rau muaj kev pheej hmoo ntawm kev tsim cov qauv martensitic hauv HAZ. Cov microstructures no nyuaj dua thiab nkig, ua rau muaj feem cuam tshuam, tshwj xeeb tshaj yog thaum muaj kev ntxhov siab lossis cuam tshuam. Kev saib xyuas tshwj xeeb, xws li preheating thiab tom qab vuam kev kho cua sov, feem ntau yuav tsum tau thaum vuam nruab nrab-carbon steel forgings los tiv thaiv cov teeb meem no.

High-carbon steels, muaj ntau dua 0.60% carbon, ua rau muaj kev sib tw loj tshaj plaws rau vuam. Cov ntsiab lus carbon siab ua rau cov hlau hardness thiab brittleness, ua rau nws yooj yim dua rau kev tawg thaum lub vuam txheej txheem. Qee zaum, cov pa roj carbon monoxide siab yuav xav tau cov txheej txheem vuam tshwj xeeb lossis tej zaum yuav tsis haum rau kev vuam txhua yam tsis muaj kev hloov pauv ntau rau cov txheej txheem. Preheating, interpass kub tswj, thiab tom qab vuam kev kho cua sov yog ib qho tseem ceeb kom tsis txhob nkig tsis ua hauj lwm nyob rau hauv high-carbon steel forgings.

Hauv cov ntsiab lus, cov ntsiab lus carbon ntawm steel plays lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov kev vam meej ntawm vuam hauv cov khoom forged. Tsawg-carbon steels yog cov feem ntau weldable, thaum nruab nrab- thiab high-carbon steels yuav tsum tau ceev faj ntxiv rau kev tswj ntawm vuam tsis xws li kev puas tsuaj xws li tawg. Kev nkag siab txog cov ntsiab lus ntawm cov pa roj carbon monoxide thiab xaiv cov txheej txheem vuam tsim nyog yog qhov tseem ceeb rau kev ua kom ruaj khov thiab ua haujlwm ntawm welded forgings hauv ntau yam kev siv.

Post lub sij hawm: Oct-16-2024